Explore Our Natural Gas Piping Services

Ideal for new appliances, renovations, and system upgrades. Installed safely, tested thoroughly, and completed to current codes for homes, cottages, and renovations across Wasaga Beach, Simcoe County, Barrie & York Region

Connecting your favorite brands

Gas Piping, Gas Re-Piping Refresh, Main Line Manifolds & Additions

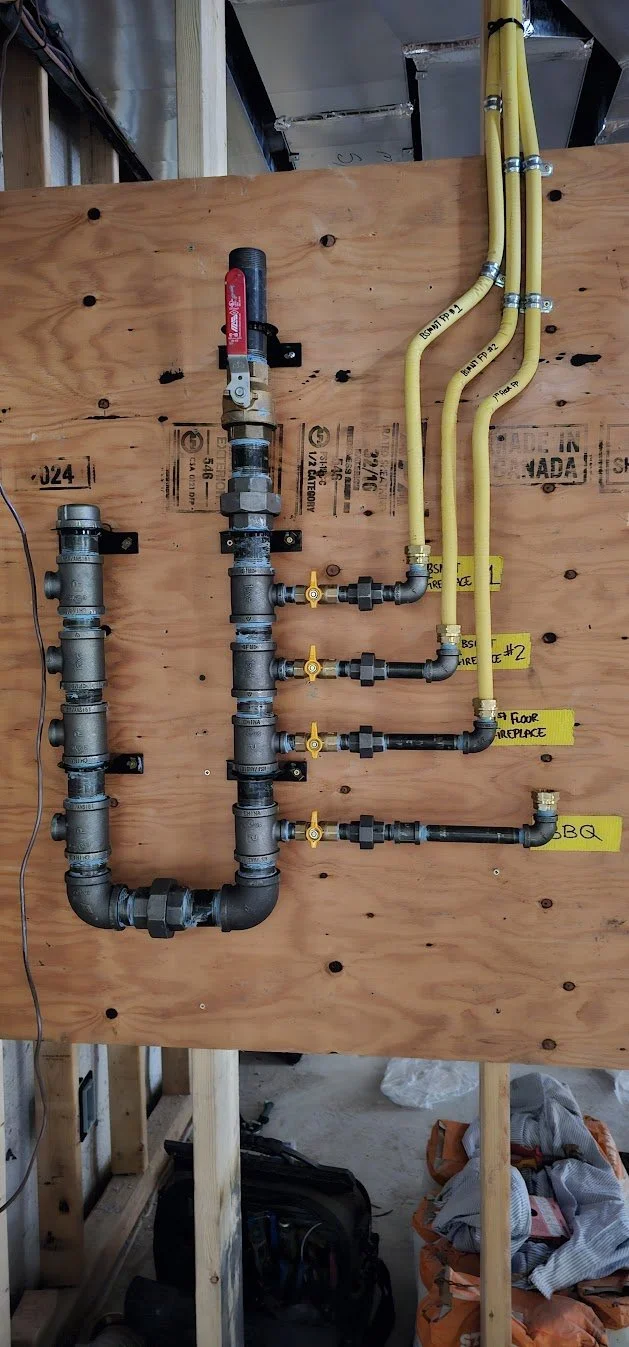

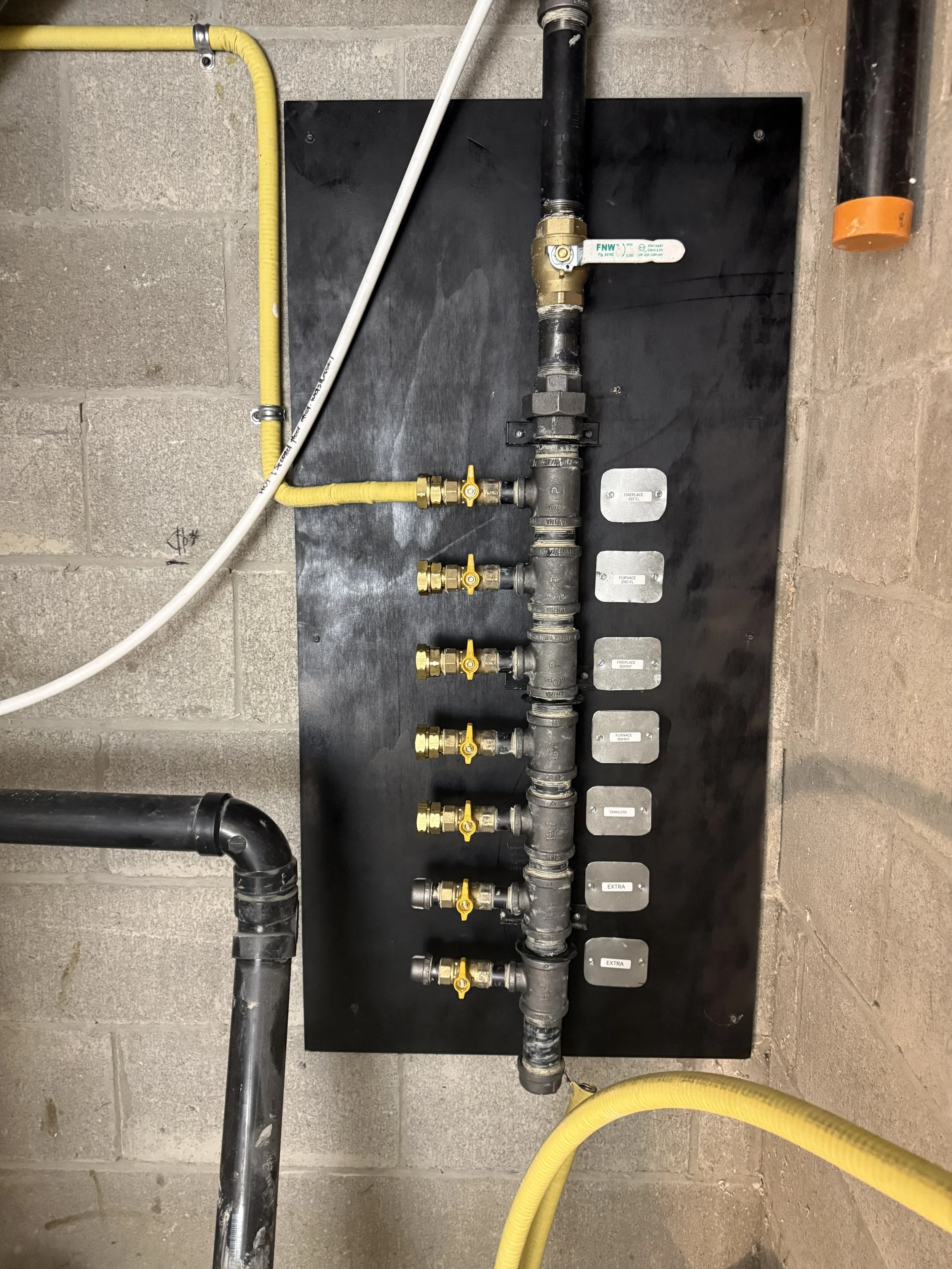

New gas lines, existing upgrades and reroute existing piping for performance & aesthetics, and build or rework manifolds for custom homes, renovations, and additions — By code, by top standards.

-

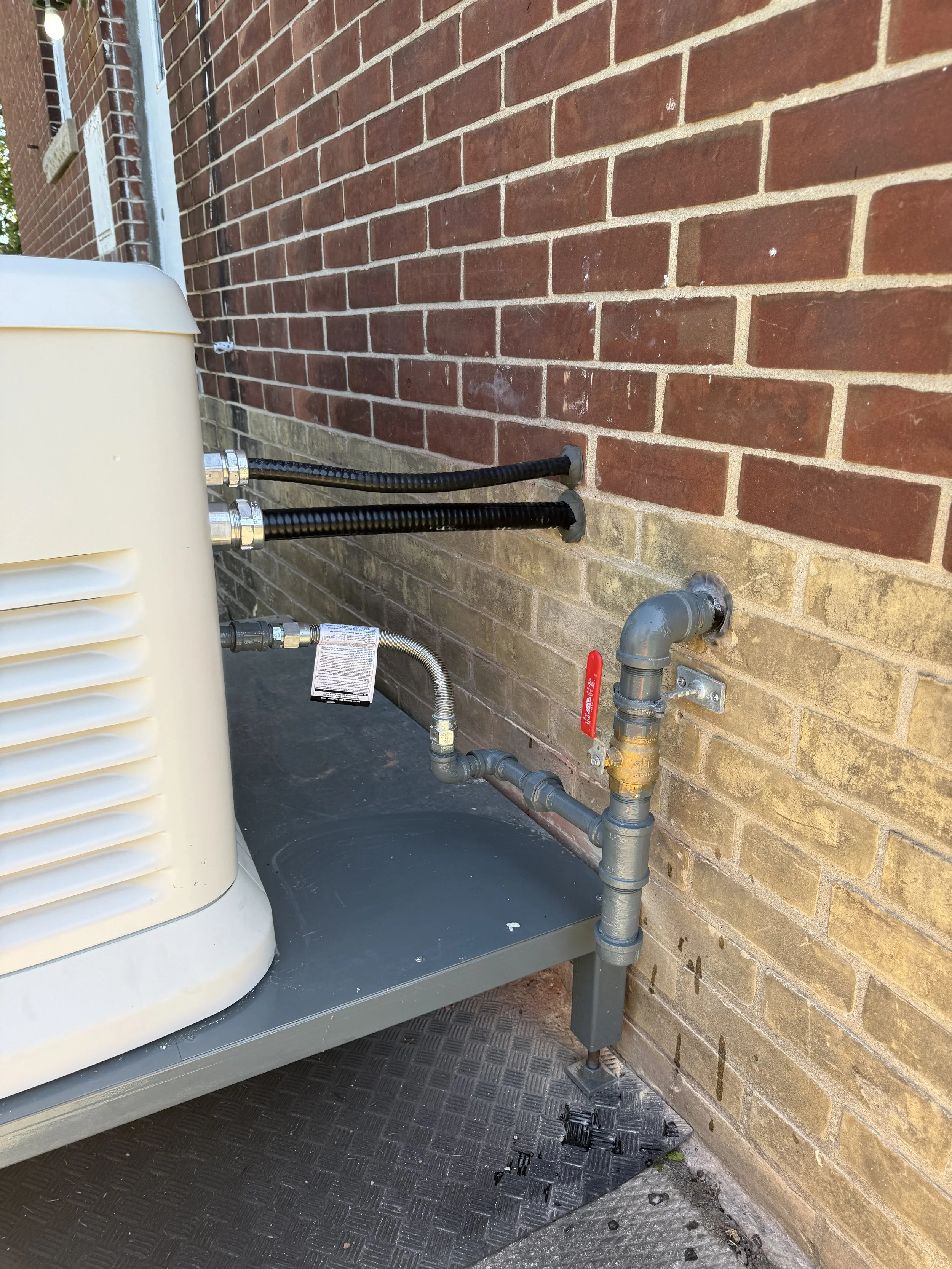

We install gas piping in black iron and Gastite for new Furnaces, Water Heaters, Manifolds, BBQ lines, fire pits, pool heaters, home additions, and kitchen renovations.

-

We rebuild and refresh existing gas lines with proper routing, new supports, added hangers, and fresh paint. Sagging, rusted, damaged, or poorly installed piping is corrected and brought back to clean, code-tight condition—exactly how it should’ve been done.

-

We build and install gas manifolds for new construction and renovation projects—clean layout, correct sizing, proper supports, and code-tight routing. Designed for multiple appliances and future capacity, built to run clean and trouble-free from day one. All your central gas appliances controlled from one location.

-

We install underground poly gas lines for appliances such as fire pits, generators, bbq’s & more, which cannot be accessed without going in the dirt. No one enjoys a beautiful firepit which has a trip hazard attached to it.

Site Review & Planning

We start with an on-site review to understand your appliances, layout, and gas demand. This includes discussing your goals, reviewing existing piping (if any), and planning the safest route for the new gas line. Coordinating start dates, expectations, material delivery, on-site power supply & access.

Proper Sizing & Load Calculation

We calculate the correct pipe size based on total gas load, distance, and future needs. Proper sizing ensures safe operation, reliable performance, and prevents pressure loss or appliance issues.

Installation

Our licensed technicians install the gas piping using approved materials and methods. All piping is securely supported, properly valved, and installed in accordance with current gas codes and manufacturer requirements.

Testing, Inspection & Commissioning

Before use, the system is pressure-tested, leak-checked, and verified gas-tight. Once approved, the line is safely commissioned and ready to serve your appliances.

Commercial Gas Piping, Gas Re-Piping Refresh, Main Line Manifolds & Additions including installation, appliance connections, pressure testing, and safety compliance.

New gas lines, existing upgrades and reroute existing piping for performance & aesthetics, and build or rework manifolds for new construction commercial buildings, renovations, and additions — By code, by top standards.

-

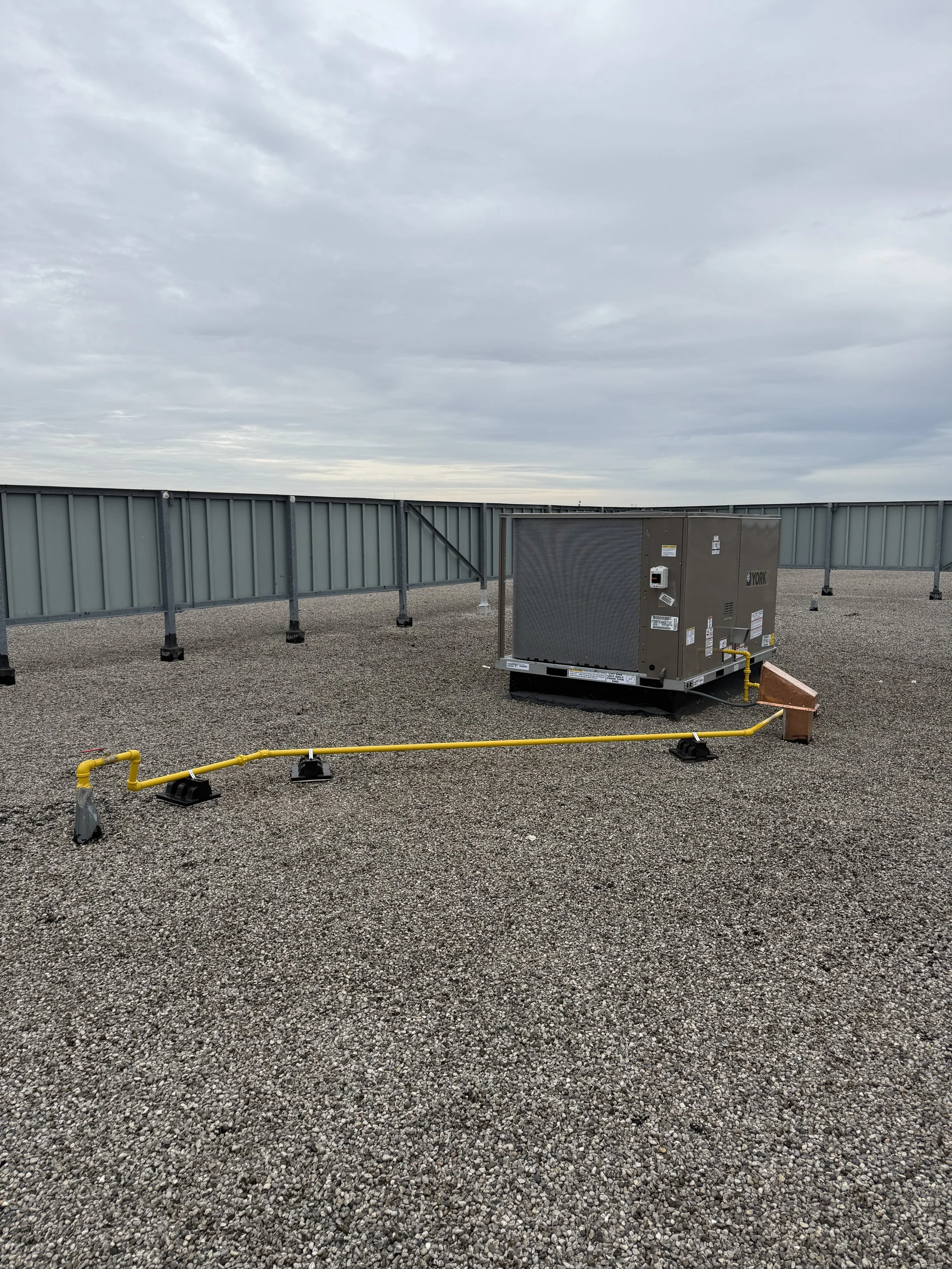

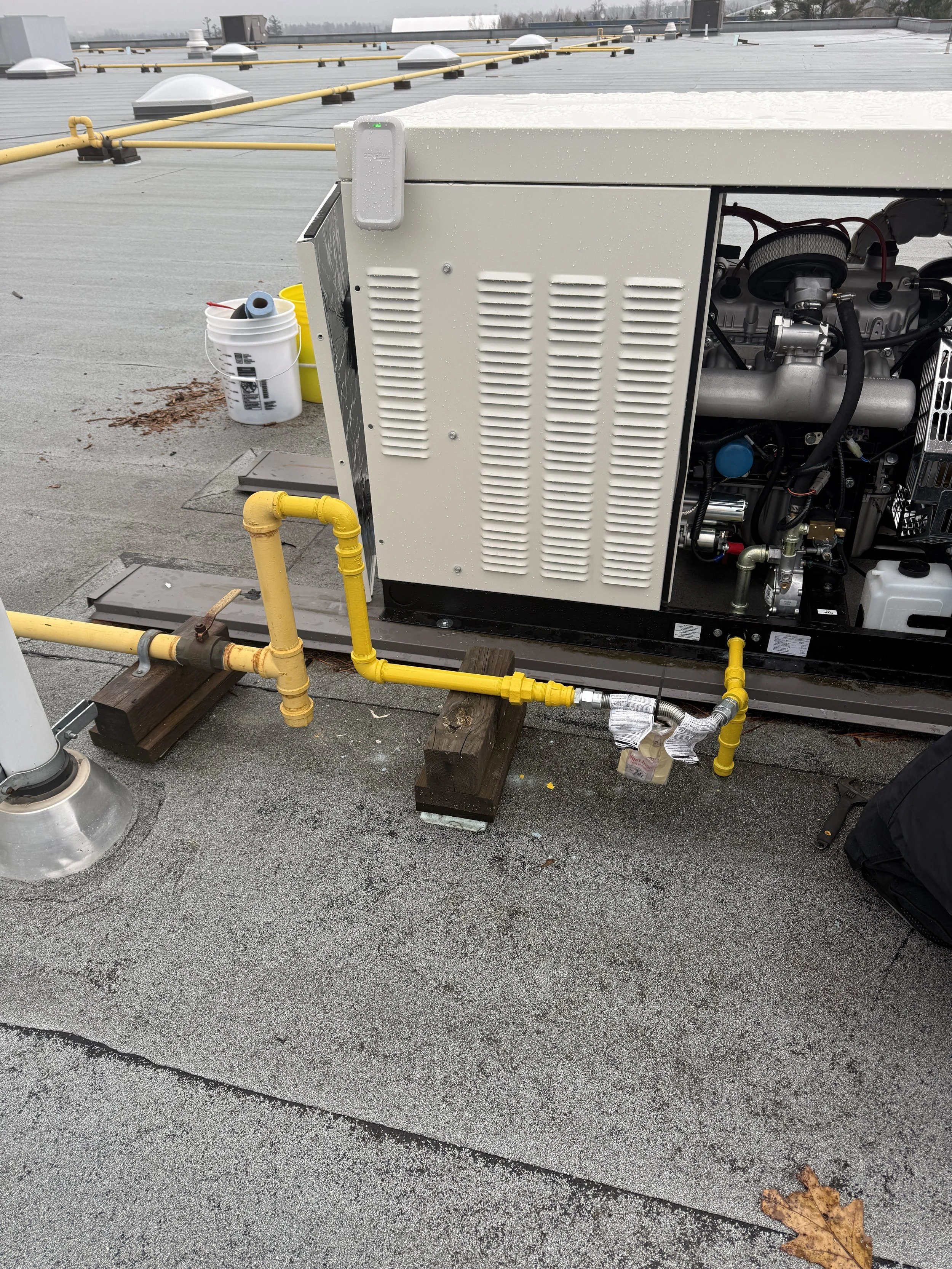

New RTU gas piping for commercial roofs. We size, design, and install Schedule 40 gas mains and branch lines for new rooftop units – laid out clean, properly supported, pressure-tested, and ready for inspection and start-up. Sizes from 1 1/4” - 2” Threaded.

-

Adding RTU’s? We re-size, re-route, and rebuild existing piping in proper Schedule 40, add isolation valves and supports, clean up hacked-in branches, and bring everything up to code so your new RTUs get the gas volume they actually need — no guessing, no shortcuts.

-

We strip out tired, crooked, under supported, rusting out, rooftop gas piping and rebuild it. Clean, straight routing, correct pitch, isolation valves where they should be, unions positioned for service, and supports set to spec so nothing sags, binds, or fights you during maintenance or change-outs. Having roofing done? Need your existing gas pipe removed and re-installed? We can handle it.

-

Unpainted rooftop gas piping isn’t just ugly — it’s not up to code. We prep, prime, and paint exposed gas lines in proper safety colors, tighten up supports, and tag valves so your RTU piping is protected from the elements, built to last. We also add identifiable markers via yellow bands, labeled markings to existing or new work.

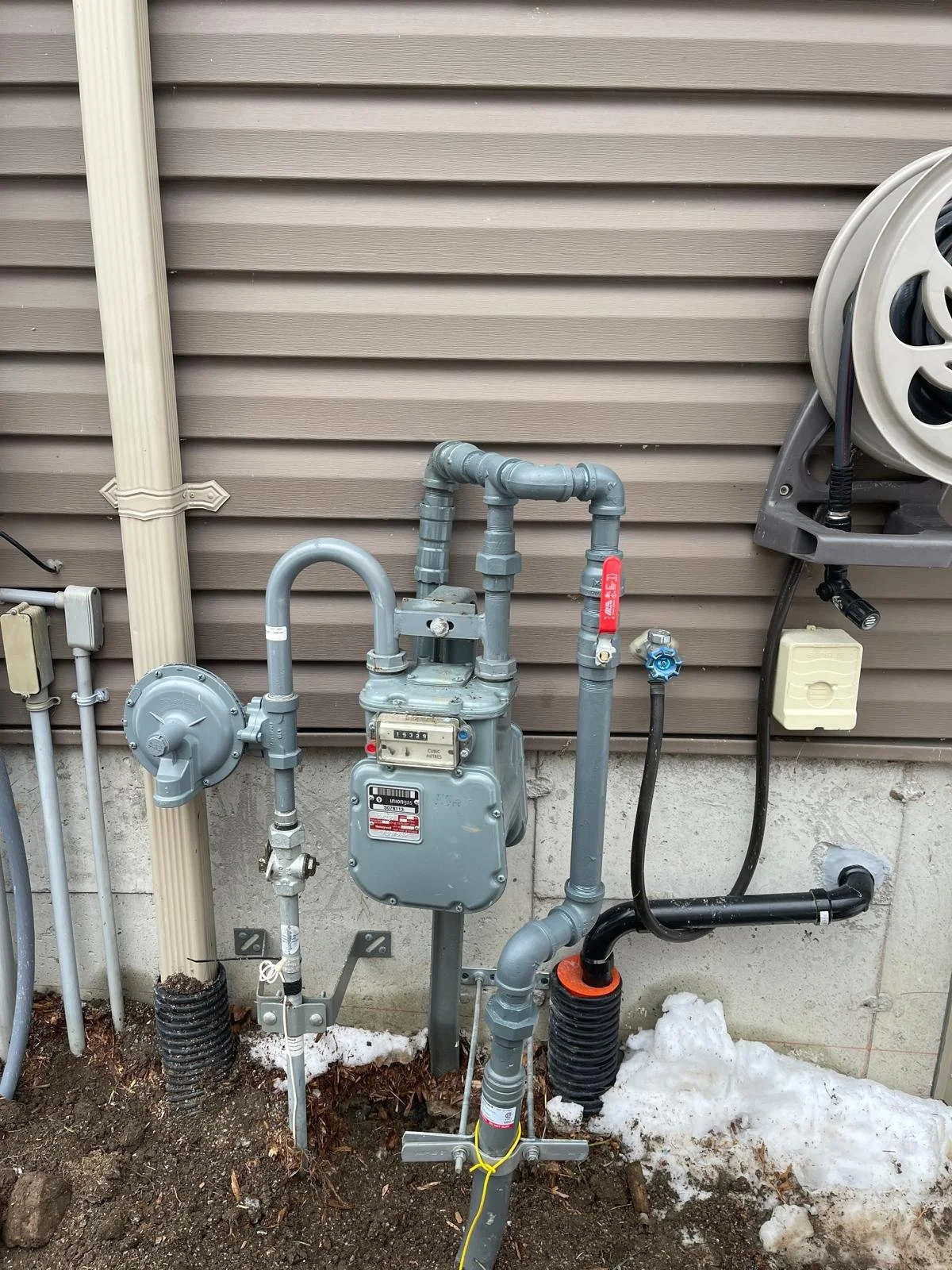

Past Project

The Bayfield Project – Barrie, ON

As winter approached, this client needed us on site as soon as possible.

This project involved a complete new natural gas supply build to serve four newly installed rooftop units (installed by others). Our team installed over 500 feet of 2” black iron threaded piping, including all required supports and isolation shut-off valves.

The scope also included coordination with Enbridge for the installation of three new gas meters, full system pressure testing, and verification that all piping was gas-tight and compliant with current code requirements. All piping was properly supported and painted to code before final connection to the rooftop units.

The system was completed safely, efficiently, and ready to serve its new owners.

Timeline: 2 days

Crew: 1 crew

Result: A clean, code-compliant installation completed with ease.

Let’s Work TogetherIf you're interested in working with us, complete the form with a few details about your project. We'll review your message and a member of our team will get back to you within 48 hours via your preferred contact method.